For an exact process control different end point detection systems can be equipped.

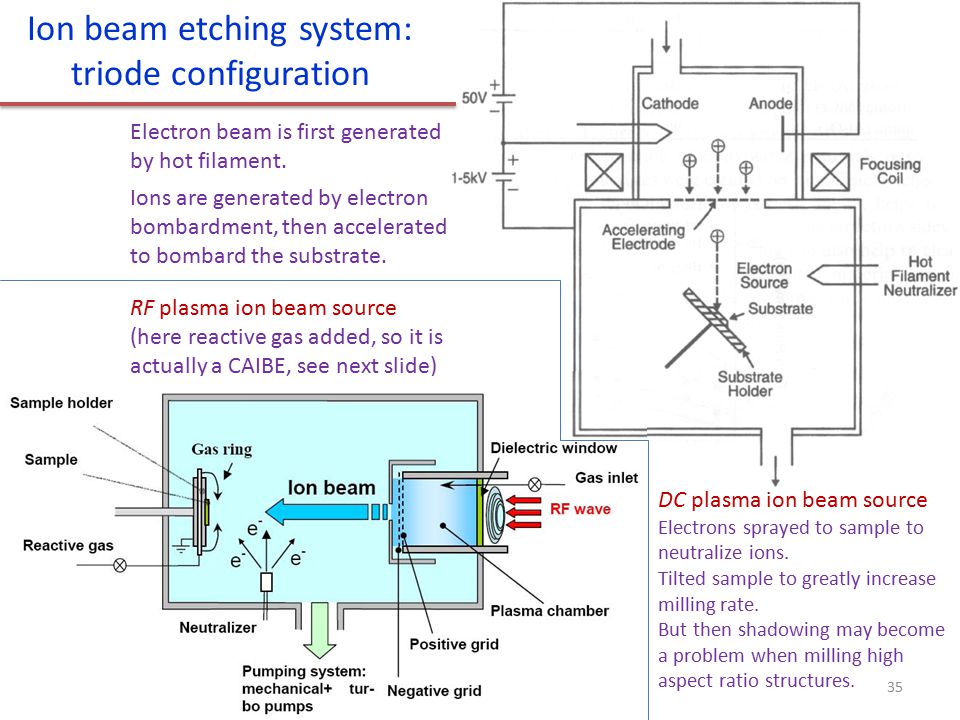

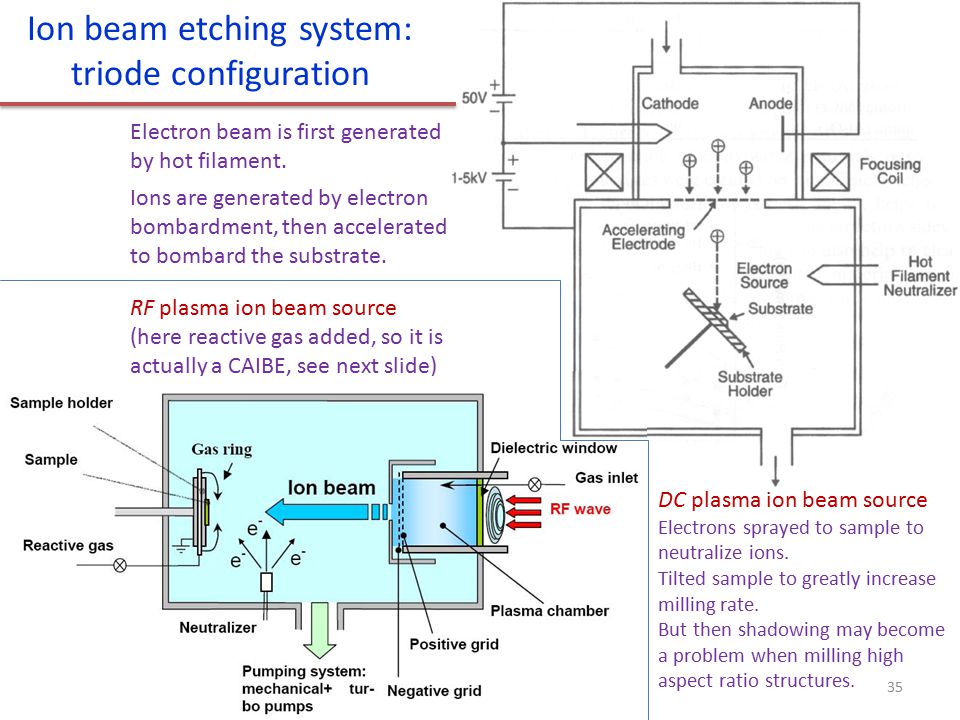

Ion beam etching system.

A variety of sample holders and ion source configurations allow for a diverse range of applications to be carried out.

Nano master s ion beam milling and etching systems are field proven fully automated systems that provide ease of use high reproducibility and reliable performance with extremely good uniformity.

System components such as shields are now easily accessible on the system itself.

This high value combination allows the customer to create thin film structures in common vacuum a significant value proposition compared to the competition.

A sample of the same material is used to determine the etching rate and set the source parameters.

Ion beam technology provides an exceptionally versatile approach to etch and deposition by offering a single tool and maximising system utilisation.

With its fully reactive gas compatibility the system enables reactive etching processes with enhanced selectivity and rate.

Oxford instruments is a leading provider of ibe technology systems.

The basic dual ion beam sputtering dibs chamber set up as comprises an etching source that precisely directs a neutralised ion beam onto a wafer located in the substrate holder.

Ion beam etching also known as ion beam milling or ion milling is the most widely used etching method for preparing solid state samples for scanning electron microscopy sem applications in this process the sample material is bombarded with high energy argon ion beams in a high vacuum chamber.

Ion beam milling systems.

Normally for good uniformity the 15cm etch source can be used for wafers up to 4 while the 30cm etch source is suitable for wafers up to 8.

Since all ion beam etching must be performed within a clean environment the manufacturer needs to focus on providing an etch module that can perform in a setting without contaminating the space.

The process and the ion source are stable although the parameters may change over time.

The z flex system combines the best of ion beam etching and ion beam sputtering.

This determination process for the etching rate is necessary for all ion beam diameter.

Full surface ion beam etching on 200 mm wafers the scia mill 200 is designed for structuring of complex multilayers of various materials.

The ion beam figuring process now begins in the omf system.